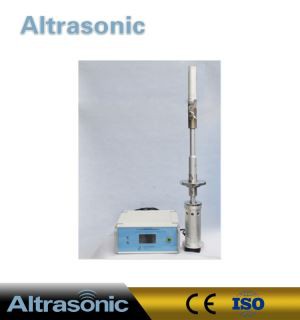

20K Ultrasonic Abrasive Assisted Machining

20K Ultrasonic Abrasive Assisted Machining

Introduction:

Ultrasonic drilling is a non-traditional, loose abrasive machining process. In this the mirror image of a shaped tool can be created in hard, brittle materials. Material removal is achieved by the direct and indirect hammering of abrasive particles against a workpiece.

In the process of Ultrasonic drilling, material is removed by micro-chipping or erosion with abrasive particles. The tool is oscillated by a piezoelectric transducer and an electric oscillator at a frequency of about 20 kHz. The tool forces the abrasive grits, in the gap between the tool and the workpiece, to impact normally on the work surface, thereby machining the work surface.

Parameters:

Product shape: HSK A63 drilling machine handle

Working frequency: 15-21KHz

Resonance point amplitude: 10um or more

Speed: 3000 r / min or less

Matching tool: carbide drilling head Φ2/Φ3/Φ4/Φ5/Φ6

Power: 1000W

Different models of connectors applied for various machine toolsBT40/BT30/HSK A63

Application:

Hard materials such as stainless steel, glass, ceramics, carbide,

Quartz, etc.

Hot Tags: 20k ultrasonic abrasive assisted machining, China, manufacturers, suppliers, factory

You Might Also Like

Send Inquiry