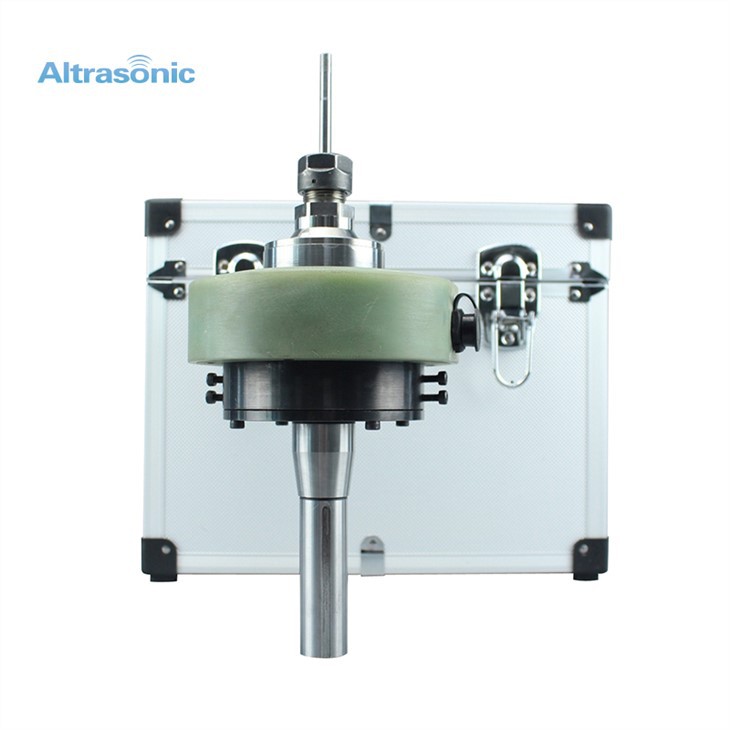

20K Ultrasonic Grinding, Milling And Drilling

20K Ultrasonic Grinding, Milling and Drilling

Introduction:

The ULTRASONIC technology from Altrasonic enables the economical machining of complex workpiece geometries in demanding high-tech materials like e. g. ceramics, glass, corundum, tungsten carbide or even composites. The kinematic overlapping of the tool rotation with an additional oscillation effects a reduction of the process forces by up to 40 % in comparison to conventional machining. Depending on the workpiece requirements, this allows higher feed and infeed, longer tool life or significantly better surface finishes of up to Ra smaller than 0.1 µm. Based on a consequent development of the ULTRASONIC technology according to the markets requirements, the ULTRASONIC 2nd generation now also is able to cover ultrasonic-assisted milling of hard to machine metal alloys or fibre reinforced materials with defined cutting edge.

Parameters:

Product shape: BT40 milling machine handleWorking frequency: 15-21KHz;Resonance point amplitude: 10um or more;Speed: 3000 r / min or lessMatching tool: carbide end mill head Φ2-Φ13;disk cutter Φ50;Power: 1000W

Product shape: HSK A63 drilling machine handleWorking frequency: 15-21KHz;Resonance point amplitude: 10um or more;Speed: 3000 r / min or lessMatching tool: carbide drilling head Φ2/Φ3/Φ4/Φ5/Φ6;Power: 1000W

Different models of connectors applied for various machine toolsBT40/BT30/HSK A63

Hot Tags: 20k ultrasonic grinding, milling and drilling, China, manufacturers, suppliers, factory

You Might Also Like

Send Inquiry